Real-Time OEE Monitoring on your Smart Phone

OEE Monitoring Software – System Overview

Welcome to our webpage for more info contact us via email here or Phone Gary – (+27 ) 06 06 24 06 55

Oee Monitoring Software

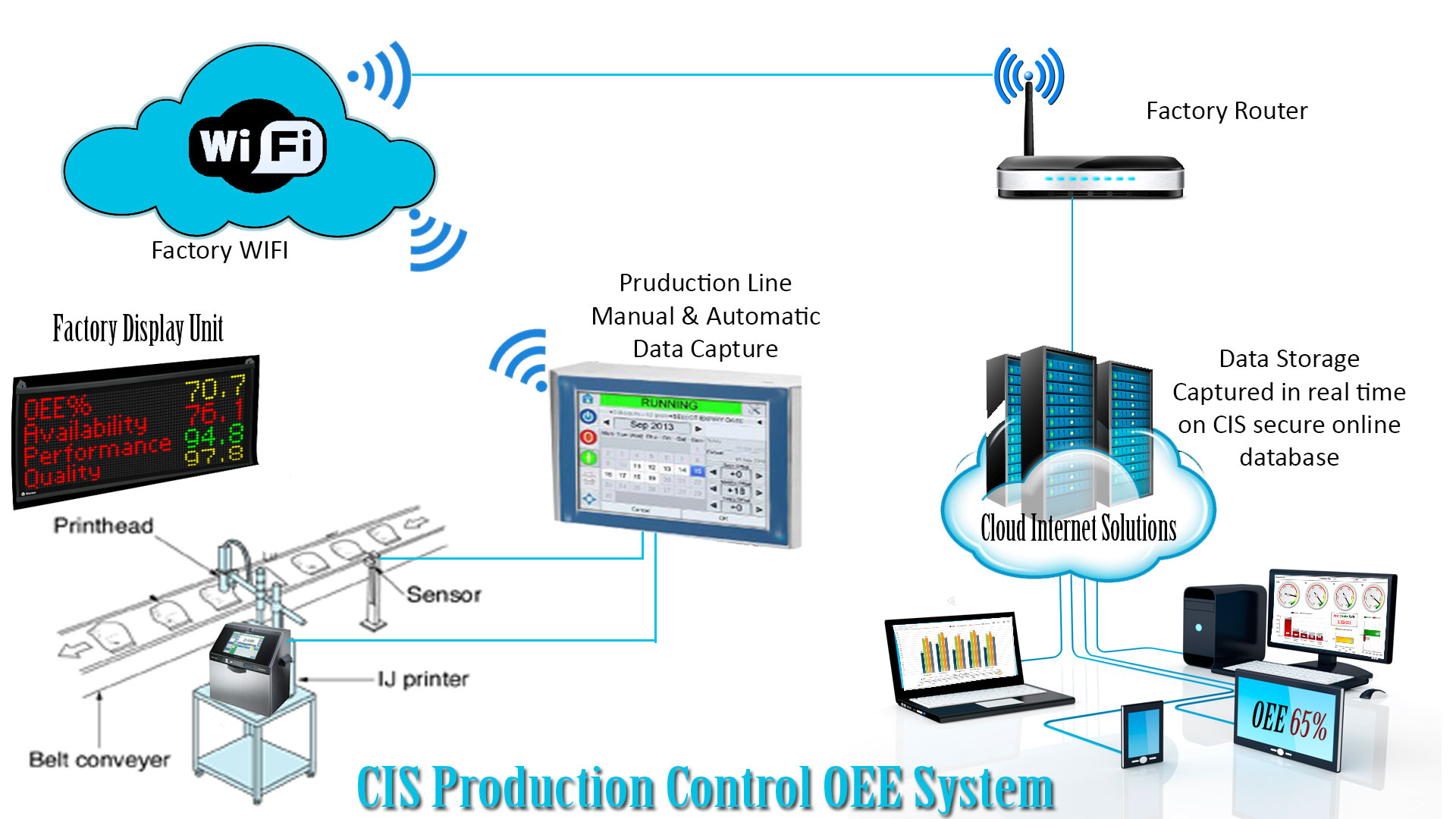

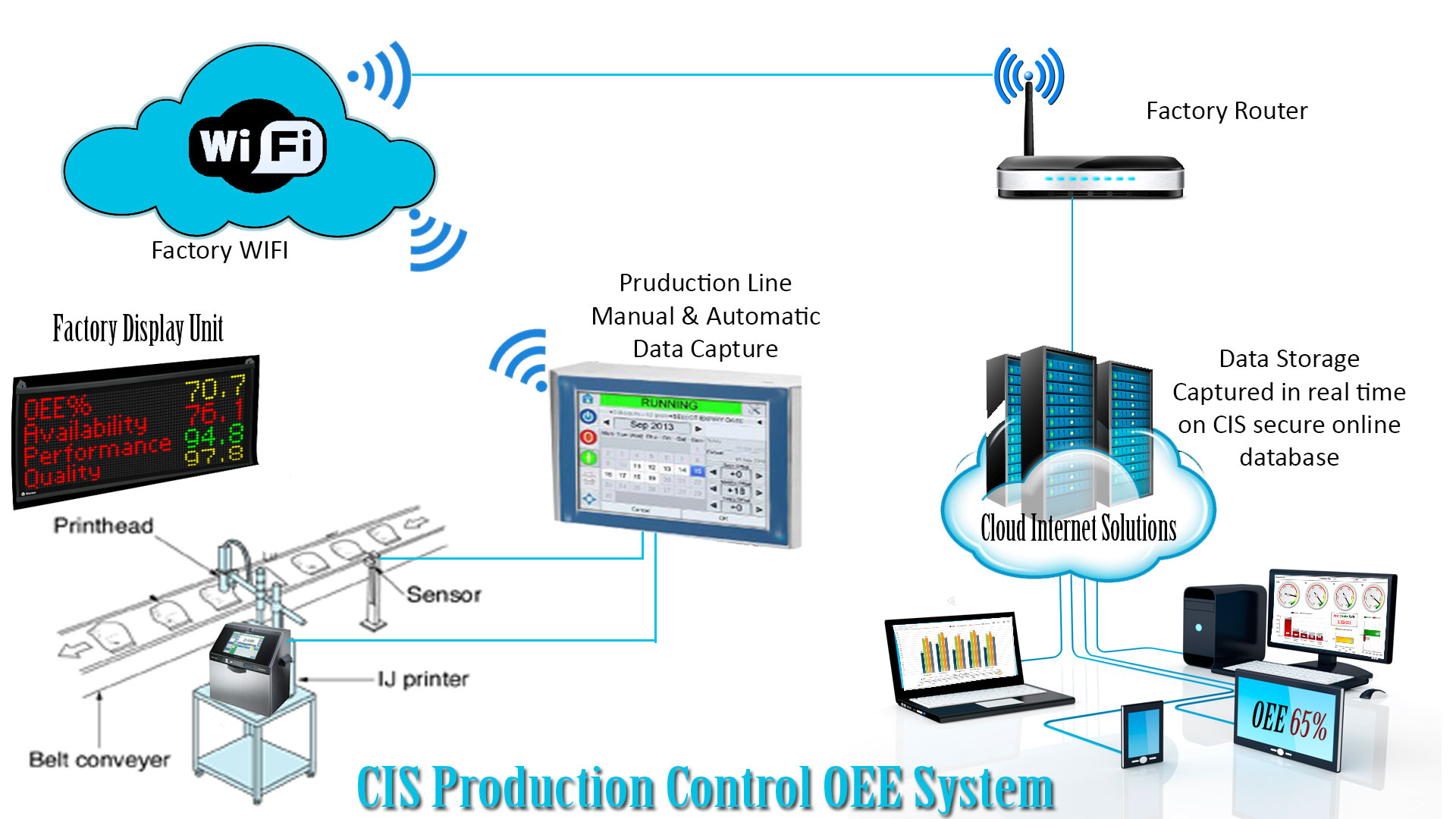

As you can see from the Schematic above your system is easy to install and maintain. The heart of the system is the Human Interface device (HID) that is uses to capture manual data.Our OEE Monitoring system offers the following Features

FEATURES

- Browser-based Application

- Cloud Version Option

- Manual and Automatic Data Collection

- Standard Interfacing and Networking Hardware

- Wired or Wireless Networking

- Operator Interface – Feedback/Actions

- Line / Shift Scheduling

- Performance Dashboards

- Live Line Status – Plant-Watch

- Output Monitoring

- Yield / Scrap / Rework Monitoring

- Pin-Point – Click-as-you-Think

- Comparative Analysis

- Daily, Weekly, Monthly Trends

- Event Trends and Timelines

- Upstream/Downstream Analysis

- Excel Export

- RePlay and pause production

- Operator Instructions

- Performance Alerts – Act-Now

- Line Speed Alarms – Real-time Speed Loss Detection

Overall Equipment Effectiveness(OEE)

We provide an efficient system for capturing data manually and automatically in real time. This Data is then used to calculate the following data in real-time to a single meaningful percentage.

Overall Equipment Effectiveness (OEE) is a crucial measure in TPM(Total Productive Maintenance) that reports on how well equipment is running. Supervisory Control And Data Acquisition (SCADA) has been used for the past 40 years to monitor and control the manufacturing processes and provide asset performance information to allow business decisions to be made.

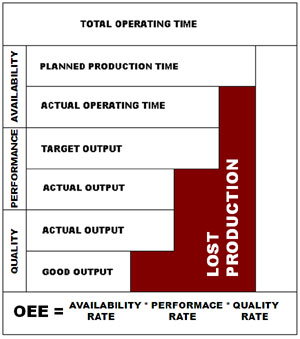

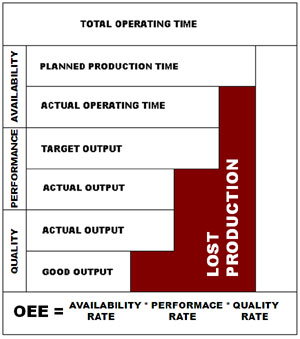

OEE factors three elements; the time the machine is actually running, the quantity of products the machine is producing, and the quantity of good output – into a single combined score.

CIS offers an easy to use and affordable solution which helps you to capture, monitor, analyse and present live data to your entire production team, helping to tackle in-line performance, process and quality issues in real-time.

Having access to critical data delivered in the right way empowers production teams to make smart decisions and provides a cost effective way to address the most common causes of efficiency loss in manufacturing.

Cloud Internet Solutions Software

Underlying metrics[edit]

In addition to the above measures, there are four underlying metrics that provide understanding as to why and where the OEE and TEEP gaps exist.

The measurements are described below:

Loading: The portion of the TEEP Metric that represents the percentage of total calendar time that is actually scheduled for operation.

Availability: The portion of the OEE Metric that represents the percentage of scheduled time that the operation is available to operate. Often referred to as Uptime.

Performance: The portion of the OEE Metric that represents the speed at which the Work Center runs as a percentage of its designed speed.

Quality: The portion of the OEE Metric that represents the Good Units produced as a percentage of the Total Units Started. Commonly referred to as First Pass Yield FPY.

Calculations for OEE and TEEP[edit]

What follows is a detailed presentation of each of the six OEE / TEEP Metrics and examples of how to perform calculations. The calculations are not particularly complicated, but care must be taken as to standards that are used as the basis. Additionally, these calculations are valid at the work center or part number level but become more complicated if rolling up to aggregate levels.[1]

Overall equipment effectiveness[edit]

OEE breaks the performance of a manufacturing unit into three separate but measurable components: Availability, Performance, and Quality. Each component points to an aspect of the process that can be targeted for improvement. OEE may be applied to any individual Work Center, or rolled up to Department or Plant levels. This tool also allows for drilling down for very specific analysis, such as a particular Part Number, Shift, or any of several other parameters. It is unlikely that any manufacturing process can run at 100% OEE. Many manufacturers benchmark their industry to set a challenging target; 85% is not uncommon.

OEE is calculated with the formula (Availability)*(Performance)*(Quality)

Using the examples given below:

(Availability= 86.6%)*(Performance=93%)*(Quality=91.3%)= (OEE=73.6%)

Alternatively, and often easier, OEE is calculated by dividing the minimum time needed to produce the parts under optimal conditions by the actual time needed to produce the parts. For example:

Total Time: 8 hour shift or 28,800 seconds, producing 14,400 parts, or one part every 2 seconds.

Fastest possible cycle time is 1.5 seconds, hence only 21,600 seconds would have been needed to produce the 14,400 parts. The remaining 7,200 seconds or 2 hours were lost.

The OEE is now the 21,600 seconds divided by 28,800 seconds (same as maximal 1.5 seconds per part divided by 2 actual seconds per part), or 75%.

Total effective equipment performance[edit]

Where OEE measures effectiveness based on scheduled hours, TEEP measures effectiveness against calendar hours, i.e.: 24 hours per day, 365 days per year.

TEEP, therefore, reports the 'bottom line' utilization of assets.

Loading[edit]

The Loading portion of the TEEP Metric represents the percentage of time that an operation is scheduled to operate compared to the total Calendar Time that is available. The Loading Metric is a pure measurement of Schedule Effectiveness and is designed to exclude the effects how well that operation may perform.

Calculation: Loading = Scheduled Time / Calendar Time

Example:

A given Work Center is scheduled to run 5 Days per Week, 24 Hours per Day.

For a given week, the Total Calendar Time is 7 Days at 24 Hours.

Loading = (5 days x 24 hours) / (7 days x 24 hours) = 71.4%

Availability[edit]

The Availability portion of the OEE Metric represents the percentage of scheduled time that the operation is available to operate. The Availability Metric is a pure measurement of Uptime that is designed to exclude the effects of Quality, Performance, and Scheduled Downtime Events. The losses due to wasted availability are called availability losses.[2]

Example: A given Work Center is scheduled to run for an 8-hour (480 minute) shift with a 30-minute scheduled break.

Operating Time = 450 Min Sched – 60 Min Unsched Downtime = 390 Minutes

Calculation: Availability = operating time / scheduled time

Availability 390 minutes / 450 minutes = 86.6%

Performance and productivity[edit]

Also known as "process rate", the Performance portion of the OEE Metric (also known as process rate) represents the speed at which the Work Center runs as a percentage of its designed speed. The Performance Metric is a pure measurement of speed that is designed to exclude the effects of Quality and Availability. The losses due to wasted performance are also often called speed losses. In practice it is often difficult to determine speed losses, and a common approach is to merely assign the remaining unknown losses as speed losses.

Calculation: Performance (Productivity) = (Parts Produced * Ideal Cycle Time) / Operating time [3]

Example:

A given Work Center is scheduled to run for an 8-hour (480 minute) shift with a 30-minute scheduled break.

Operating Time = 450 Min Sched – 60 Min Unsched Downtime = 390 Minutes

The Standard Rate for the part being produced is 40 Units/Hour or 1.5 Minutes/Unit

The Work Center produces 242 Total Units during the shift. Note: The basis is Total Units, not Good Units. The Performance metric does not penalize for Quality.

Time to Produce Parts = 242 Units * 1.5 Minutes/Unit = 363 Minutes

Performance (Productivity) = 363 Minutes / 390 Minutes = 93.0%

Quality[edit]

The Quality portion of the OEE Metric represents the Good Units produced as a percentage of the Total Units Started. The Quality Metric is a pure measurement of Process Yield that is designed to exclude the effects of Availability and Performance. The losses due to defects and rework are called quality losses.

Calculation: Quality = (Units produced - defective units) / (Units produced)

Example:

242 Units are produced. 21 are defective.

(242 units produced - 21 defective units) = 221 units

221 good units / 242 total units produced = 91.32%

"Six Big Losses"[edit]

Example of OEE and Six Loss calculation

To be able to better determine what is contributing to the greatest loss and so what areas should be targeted to improve the performance, these categories (Availability, Performance and Quality) have been subdivided further into what is known as the ‘Six Big Loses’ to OEE.[4]

These are categorized as follows:

Availability Performance Quality

Planned Downtime Minor Stops Production Rejects

Breakdowns Speed Loss Rejects on Start up

The reason for identifying the losses in these categories is so that specific countermeasures[5] can be applied to reduce the loss and improve the overall OEE. The Six Loss categories can be calculated manually, but there are also a plethora of simple calculators online.[6][7]

Heuristic[edit]

OEE is useful as a heuristic, but can break down in several circumstances. For example, it may be far more costly to run a facility at certain times. Performance and quality may not be independent of each other or of availability and loading. Experience may develop over time. Since the performance of shop floor managers is at least sometimes compared to the OEE, these numbers are often not reliable, and there are numerous ways to fudge these numbers.[8]

OEE has properties of a geometric mean. As such it punishes variability among its subcomponents. For example 20% * 80% = 16%, whereas 50% * 50% = 25%. When there are asymmetric costs associated with one or more of the components, then the model may become less appropriate.

Consider a system where the cost of error is exceptionally high. In such a condition, higher quality may be far more important in a proper evaluation of effectiveness than performance or availability. OEE also to some extent assumes a closed system and a potentially static one. If one can bring in additional resources (or lease out unused resources to other projects or business units) then it may be more appropriate for example to use an expected net present value analysis.

Variability in flow also can introduce important costs and risks that may merit further modeling. Sensitivity analysis and measures of change may be helpful.

Underlying metrics[edit]

In addition to the above measures, there are four underlying metrics that provide understanding as to why and where the OEE and TEEP gaps exist.

The measurements are described below:

Loading: The portion of the TEEP Metric that represents the percentage of total calendar time that is actually scheduled for operation.

Availability: The portion of the OEE Metric that represents the percentage of scheduled time that the operation is available to operate. Often referred to as Uptime.

Performance: The portion of the OEE Metric that represents the speed at which the Work Center runs as a percentage of its designed speed.

Quality: The portion of the OEE Metric that represents the Good Units produced as a percentage of the Total Units Started. Commonly referred to as First Pass Yield FPY.

Calculations for OEE and TEEP[edit]

What follows is a detailed presentation of each of the six OEE / TEEP Metrics and examples of how to perform calculations. The calculations are not particularly complicated, but care must be taken as to standards that are used as the basis. Additionally, these calculations are valid at the work center or part number level but become more complicated if rolling up to aggregate levels.[1]

Overall equipment effectiveness[edit]

OEE breaks the performance of a manufacturing unit into three separate but measurable components: Availability, Performance, and Quality. Each component points to an aspect of the process that can be targeted for improvement. OEE may be applied to any individual Work Center, or rolled up to Department or Plant levels. This tool also allows for drilling down for very specific analysis, such as a particular Part Number, Shift, or any of several other parameters. It is unlikely that any manufacturing process can run at 100% OEE. Many manufacturers benchmark their industry to set a challenging target; 85% is not uncommon.

OEE is calculated with the formula (Availability)*(Performance)*(Quality)

Using the examples given below:

(Availability= 86.6%)*(Performance=93%)*(Quality=91.3%)= (OEE=73.6%)

Alternatively, and often easier, OEE is calculated by dividing the minimum time needed to produce the parts under optimal conditions by the actual time needed to produce the parts. For example:

Total Time: 8 hour shift or 28,800 seconds, producing 14,400 parts, or one part every 2 seconds.

Fastest possible cycle time is 1.5 seconds, hence only 21,600 seconds would have been needed to produce the 14,400 parts. The remaining 7,200 seconds or 2 hours were lost.

The OEE is now the 21,600 seconds divided by 28,800 seconds (same as maximal 1.5 seconds per part divided by 2 actual seconds per part), or 75%.

Total effective equipment performance[edit]

Where OEE measures effectiveness based on scheduled hours, TEEP measures effectiveness against calendar hours, i.e.: 24 hours per day, 365 days per year.

TEEP, therefore, reports the 'bottom line' utilization of assets.

Loading[edit]

The Loading portion of the TEEP Metric represents the percentage of time that an operation is scheduled to operate compared to the total Calendar Time that is available. The Loading Metric is a pure measurement of Schedule Effectiveness and is designed to exclude the effects how well that operation may perform.

Calculation: Loading = Scheduled Time / Calendar Time

Example:

A given Work Center is scheduled to run 5 Days per Week, 24 Hours per Day.

For a given week, the Total Calendar Time is 7 Days at 24 Hours.

Loading = (5 days x 24 hours) / (7 days x 24 hours) = 71.4%

Availability[edit]

The Availability portion of the OEE Metric represents the percentage of scheduled time that the operation is available to operate. The Availability Metric is a pure measurement of Uptime that is designed to exclude the effects of Quality, Performance, and Scheduled Downtime Events. The losses due to wasted availability are called availability losses.[2]

Example: A given Work Center is scheduled to run for an 8-hour (480 minute) shift with a 30-minute scheduled break.

Operating Time = 450 Min Sched – 60 Min Unsched Downtime = 390 Minutes

Calculation: Availability = operating time / scheduled time

Availability 390 minutes / 450 minutes = 86.6%

Performance and productivity[edit]

Also known as "process rate", the Performance portion of the OEE Metric (also known as process rate) represents the speed at which the Work Center runs as a percentage of its designed speed. The Performance Metric is a pure measurement of speed that is designed to exclude the effects of Quality and Availability. The losses due to wasted performance are also often called speed losses. In practice it is often difficult to determine speed losses, and a common approach is to merely assign the remaining unknown losses as speed losses.

Calculation: Performance (Productivity) = (Parts Produced * Ideal Cycle Time) / Operating time [3]

Example:

A given Work Center is scheduled to run for an 8-hour (480 minute) shift with a 30-minute scheduled break.

Operating Time = 450 Min Sched – 60 Min Unsched Downtime = 390 Minutes

The Standard Rate for the part being produced is 40 Units/Hour or 1.5 Minutes/Unit

The Work Center produces 242 Total Units during the shift. Note: The basis is Total Units, not Good Units. The Performance metric does not penalize for Quality.

Time to Produce Parts = 242 Units * 1.5 Minutes/Unit = 363 Minutes

Performance (Productivity) = 363 Minutes / 390 Minutes = 93.0%

Quality[edit]

The Quality portion of the OEE Metric represents the Good Units produced as a percentage of the Total Units Started. The Quality Metric is a pure measurement of Process Yield that is designed to exclude the effects of Availability and Performance. The losses due to defects and rework are called quality losses.

Calculation: Quality = (Units produced - defective units) / (Units produced)

Example:

242 Units are produced. 21 are defective.

(242 units produced - 21 defective units) = 221 units

221 good units / 242 total units produced = 91.32%

"Six Big Losses"[edit]

Example of OEE and Six Loss calculation

To be able to better determine what is contributing to the greatest loss and so what areas should be targeted to improve the performance, these categories (Availability, Performance and Quality) have been subdivided further into what is known as the ‘Six Big Loses’ to OEE.[4]

These are categorized as follows:

Availability Performance Quality

Planned Downtime Minor Stops Production Rejects

Breakdowns Speed Loss Rejects on Start up

The reason for identifying the losses in these categories is so that specific countermeasures[5] can be applied to reduce the loss and improve the overall OEE. The Six Loss categories can be calculated manually, but there are also a plethora of simple calculators online.[6][7]

Heuristic[edit]

OEE is useful as a heuristic, but can break down in several circumstances. For example, it may be far more costly to run a facility at certain times. Performance and quality may not be independent of each other or of availability and loading. Experience may develop over time. Since the performance of shop floor managers is at least sometimes compared to the OEE, these numbers are often not reliable, and there are numerous ways to fudge these numbers.[8]

OEE has properties of a geometric mean. As such it punishes variability among its subcomponents. For example 20% * 80% = 16%, whereas 50% * 50% = 25%. When there are asymmetric costs associated with one or more of the components, then the model may become less appropriate.

Consider a system where the cost of error is exceptionally high. In such a condition, higher quality may be far more important in a proper evaluation of effectiveness than performance or availability. OEE also to some extent assumes a closed system and a potentially static one. If one can bring in additional resources (or lease out unused resources to other projects or business units) then it may be more appropriate for example to use an expected net present value analysis.

Variability in flow also can introduce important costs and risks that may merit further modeling. Sensitivity analysis and measures of change may be helpful.

Underlying metrics[edit]

In addition to the above measures, there are four underlying metrics that provide understanding as to why and where the OEE and TEEP gaps exist.

The measurements are described below:

Loading: The portion of the TEEP Metric that represents the percentage of total calendar time that is actually scheduled for operation.

Availability: The portion of the OEE Metric that represents the percentage of scheduled time that the operation is available to operate. Often referred to as Uptime.

Performance: The portion of the OEE Metric that represents the speed at which the Work Center runs as a percentage of its designed speed.

Quality: The portion of the OEE Metric that represents the Good Units produced as a percentage of the Total Units Started. Commonly referred to as First Pass Yield FPY.

Calculations for OEE and TEEP[edit]

What follows is a detailed presentation of each of the six OEE / TEEP Metrics and examples of how to perform calculations. The calculations are not particularly complicated, but care must be taken as to standards that are used as the basis. Additionally, these calculations are valid at the work center or part number level but become more complicated if rolling up to aggregate levels.[1]

Overall equipment effectiveness[edit]

OEE breaks the performance of a manufacturing unit into three separate but measurable components: Availability, Performance, and Quality. Each component points to an aspect of the process that can be targeted for improvement. OEE may be applied to any individual Work Center, or rolled up to Department or Plant levels. This tool also allows for drilling down for very specific analysis, such as a particular Part Number, Shift, or any of several other parameters. It is unlikely that any manufacturing process can run at 100% OEE. Many manufacturers benchmark their industry to set a challenging target; 85% is not uncommon.

OEE is calculated with the formula (Availability)*(Performance)*(Quality)

Using the examples given below:

(Availability= 86.6%)*(Performance=93%)*(Quality=91.3%)= (OEE=73.6%)

Alternatively, and often easier, OEE is calculated by dividing the minimum time needed to produce the parts under optimal conditions by the actual time needed to produce the parts. For example:

Total Time: 8 hour shift or 28,800 seconds, producing 14,400 parts, or one part every 2 seconds.

Fastest possible cycle time is 1.5 seconds, hence only 21,600 seconds would have been needed to produce the 14,400 parts. The remaining 7,200 seconds or 2 hours were lost.

The OEE is now the 21,600 seconds divided by 28,800 seconds (same as maximal 1.5 seconds per part divided by 2 actual seconds per part), or 75%.

Total effective equipment performance[edit]

Where OEE measures effectiveness based on scheduled hours, TEEP measures effectiveness against calendar hours, i.e.: 24 hours per day, 365 days per year.

TEEP, therefore, reports the 'bottom line' utilization of assets.

Loading[edit]

The Loading portion of the TEEP Metric represents the percentage of time that an operation is scheduled to operate compared to the total Calendar Time that is available. The Loading Metric is a pure measurement of Schedule Effectiveness and is designed to exclude the effects how well that operation may perform.

Calculation: Loading = Scheduled Time / Calendar Time

Example:

A given Work Center is scheduled to run 5 Days per Week, 24 Hours per Day.

For a given week, the Total Calendar Time is 7 Days at 24 Hours.

Loading = (5 days x 24 hours) / (7 days x 24 hours) = 71.4%

Availability[edit]

The Availability portion of the OEE Metric represents the percentage of scheduled time that the operation is available to operate. The Availability Metric is a pure measurement of Uptime that is designed to exclude the effects of Quality, Performance, and Scheduled Downtime Events. The losses due to wasted availability are called availability losses.[2]

Example: A given Work Center is scheduled to run for an 8-hour (480 minute) shift with a 30-minute scheduled break.

Operating Time = 450 Min Sched – 60 Min Unsched Downtime = 390 Minutes

Calculation: Availability = operating time / scheduled time

Availability 390 minutes / 450 minutes = 86.6%

Performance and productivity[edit]

Also known as "process rate", the Performance portion of the OEE Metric (also known as process rate) represents the speed at which the Work Center runs as a percentage of its designed speed. The Performance Metric is a pure measurement of speed that is designed to exclude the effects of Quality and Availability. The losses due to wasted performance are also often called speed losses. In practice it is often difficult to determine speed losses, and a common approach is to merely assign the remaining unknown losses as speed losses.

Calculation: Performance (Productivity) = (Parts Produced * Ideal Cycle Time) / Operating time [3]

Example:

A given Work Center is scheduled to run for an 8-hour (480 minute) shift with a 30-minute scheduled break.

Operating Time = 450 Min Sched – 60 Min Unsched Downtime = 390 Minutes

The Standard Rate for the part being produced is 40 Units/Hour or 1.5 Minutes/Unit

The Work Center produces 242 Total Units during the shift. Note: The basis is Total Units, not Good Units. The Performance metric does not penalize for Quality.

Time to Produce Parts = 242 Units * 1.5 Minutes/Unit = 363 Minutes

Performance (Productivity) = 363 Minutes / 390 Minutes = 93.0%

Quality[edit]

The Quality portion of the OEE Metric represents the Good Units produced as a percentage of the Total Units Started. The Quality Metric is a pure measurement of Process Yield that is designed to exclude the effects of Availability and Performance. The losses due to defects and rework are called quality losses.

Calculation: Quality = (Units produced - defective units) / (Units produced)

Example:

242 Units are produced. 21 are defective.

(242 units produced - 21 defective units) = 221 units

221 good units / 242 total units produced = 91.32%

"Six Big Losses"[edit]

Example of OEE and Six Loss calculation

To be able to better determine what is contributing to the greatest loss and so what areas should be targeted to improve the performance, these categories (Availability, Performance and Quality) have been subdivided further into what is known as the ‘Six Big Loses’ to OEE.[4]

These are categorized as follows:

Availability Performance Quality

Planned Downtime Minor Stops Production Rejects

Breakdowns Speed Loss Rejects on Start up

The reason for identifying the losses in these categories is so that specific countermeasures[5] can be applied to reduce the loss and improve the overall OEE. The Six Loss categories can be calculated manually, but there are also a plethora of simple calculators online.[6][7]

Heuristic[edit]

OEE is useful as a heuristic, but can break down in several circumstances. For example, it may be far more costly to run a facility at certain times. Performance and quality may not be independent of each other or of availability and loading. Experience may develop over time. Since the performance of shop floor managers is at least sometimes compared to the OEE, these numbers are often not reliable, and there are numerous ways to fudge these numbers.[8]

OEE has properties of a geometric mean. As such it punishes variability among its subcomponents. For example 20% * 80% = 16%, whereas 50% * 50% = 25%. When there are asymmetric costs associated with one or more of the components, then the model may become less appropriate.

Consider a system where the cost of error is exceptionally high. In such a condition, higher quality may be far more important in a proper evaluation of effectiveness than performance or availability. OEE also to some extent assumes a closed system and a potentially static one. If one can bring in additional resources (or lease out unused resources to other projects or business units) then it may be more appropriate for example to use an expected net present value analysis.

Variability in flow also can introduce important costs and risks that may merit further modeling. Sensitivity analysis and measures of change may be helpful.

QUICK DEFINITION

OEE is an abbreviation for the manufacturing metric Overall Equipment Effectiveness. OEE takes into account the various sub components of the manufacturing process – Availability, Performance and Quality. After the various factors are taken into account the result is expressed as a percentage. This percentage can be viewed as a snapshot of the current production efficiency for a machine, line or cell.

OEE= Availability x Performance x Quality

EXPANDED DEFINITION

Manufacturing a product is a complex process. Without metrics and guidelines it is very easy to lose control and have your business managed by your production. OEE is a tool that combines multiple manufacturing issues and data points to provide information about the process. By analyzing and calculating data it also functions as a framework for root cause analysis. Through a documented process of combining the underlying data OEE provides specific process information. All members of the manufacturing team, from assembly technicians to financial personnel can use the data to understand the current state of the manufacturing process. By having a predetermined framework of the impact of machine availability, performance and quality, OEE provides a framework to track underlying issues and root causes. OEE also provides a framework for improvements in the manufacturing process. By using key OEE concepts such as The Six Big Losses waste exposed by tracking OEE can be understood and efficiencies can be improved.

The components of this framework are:

OEE

Availability

Performance

Quality

OEE is a very simple metric to immediately indicate the current status of a manufacturing process and also a complex tool allowing you to understand the effect of the various issues in the manufacturing process and how they affect the entire process.

OEE= Availability x Performance x Quality

We have one simple goal. Improving your manufacturing productivity. Introducing the XL Productivity Appliance™. Let the improvements begin.

Availability refers to the machine or cell being available for production when scheduled. At the most basic level, when a process is running it is creating value for the end user. When a process is stopped, it's creating a cost with no associated value. Whether it's due to mechanical failure, raw materials or operator issues, the cell or machine is either producing or not producing. By comparing scheduled run time to actual run time, the availability component of OEE allows for a determination of lost production due to down time.

Performance is determined by how much waste is created through running at less than optimal speed. By comparing the actual cycle times against ideal cycle times, OEE allows for a determination of how much production was lost by cycles that did not meet the ideal cycle time.

Quality focuses on identifying time that was wasted by producing a product that does not meet quality standards. By comparing the quantity of good to reject parts the percent of time actually adding value by producing good product is exposed.

HOW CAN OEE HELP MY ORGANIZATION?

By itself, OEE only provides data about your manufacturing process. Companies that use OEE as a metric have found success when combining it with general lean manufacturing programs and also as part of TPM systems. When using OEE with these systems the benefits become significant:

Directly tie production efficiencies to fiscal reporting

Reduce investigation time for root cause analysis

Shorten equipment ROI through increased utilization

Decrease costs through waste elimination

Increase customer satisfaction through quality improvement

OEE allows companies to pull separate business functions together with a single useful metric.

Overall Equipment Effectiveness

How to define OEE for optimal Loss visualisation: OEE Industry Standard

Questions about OEE? Ask your free OEE Coach!

In an ideal factory, equipment would operate 100 percent of the time at 100 percent capacity, with an output of 100 percent good quality.

In real life, however, this situation is rare.

The difference between the ideal and the actual situation is due to losses. Calculating the overall equipment effectiveness (OEE) rate is a crucial element of any serious commitment to reduce equipment- and process-related wastes through total productive maintenance (TPM) and other lean manufacturing methods like Operational Excellence, Six Sigma or World Class Manufacturing.

Introduction

TPM

The Six Big Losses

OVERALL EQUIPMENT EFFECTIVENESS and the TPM vision

The Overall Equipment Effectiveness Metric

The elements of OVERALL EQUIPMENT EFFECTIVENESS

The Goal and Benefits of OEE Measurement

INTRODUCTION

TOTAL PRODUCTIVE MAINTENANCE, THE SIX BIG LOSSES, AND OVERALL EQUIPMENT EFFECTIVENESS AND THE TPM VISION

TOTAL PRODUCTIVE MAINTENANCE

Total productive maintenance (TPM) was first defined in 1971 by the Japan Institute of Plant Maintenance (JIPM). TPM is a company wide strategy to increase the effectiveness of production environments, especially through methods for increasing the effectiveness of equipment.

TPM became more broadly known in the Western world in the late 1980s when Productivity, Inc. published English editions of two books by JIPM expert Seiichi Nakajima: Introduction to TPM and TPM Development Program. TPM implementation involves applying continuous improvement methods to reduce losses. Because the actual process of adding value to products usually involves machines and equipment, TPM focuses its improvement activities on equipment-related losses.

In an ideal factory, equipment would operate 100 percent of the time at 100 percent capacity, with an output of 100 percent good quality.

In real life, however, this is rare. The difference between the ideal and the actual situation is due to losses. Equipment operators face the results of these losses on a daily basis. TPM gives them the tools to identify the losses and make improvements.

A key strategy in TPM is identifying and reducing what we call the six big losses.

THE SIX BIG LOSSES

Looking at machine operation, we distinguish six types of waste we refer to as losses, because they reflect lost effectiveness of the equipment

These six big losses are grouped in three major categories: downtime, speed losses, and defect losses.

The Six Big Losses

Loss Categories The Six Big Losses

Downtime

(lost availability)

Equipment failures

Waiting (i.e.Setup and adjustments)

Speed losses

(lost performance)

Idling and minor stoppages

Reduced speed operation

Defect losses

(lost quality)

Scrap and rework

Startup losses

(Currently, JIPM identifies cutting blade losses as a seventh loss. Since this is not a common loss to all machines, cutting blade losses should be categorized as either performance or downtime losses for the purpose of using the OEE Toolkit

Downtime

Downtime refers to time when the machine should be running, but it stands still. Downtime includes two main types of loss: equipment failures, and all kinds of waiting, like setup and adjustments, no raw material.

Equipment Failures

Sudden and unexpected equipment failures, or breakdowns, are an obvious cause of loss, since an equipment failure means that the machine is not producing any output.

Setup and Adjustments

Most machine changeovers require some period of shutdown so that internal tools can be exchanged. The time between the end of production of the last good part and the end of production of the next good part is downtime. This downtime loss often includes substantial time spent making adjustments until the machine gives acceptable quality on the new part.

Speed Losses

A speed loss means that the equipment is running, but it is not running at its maximum designed speed. Speed losses include two main types of loss: idling and minor stoppages, and reduced speed operation.

Idling and Minor Stoppages

When a machine is not running smoothly and at a stable speed, it will lose speed and obstruct a smooth flow. The idling and stoppages in this case are caused not by technical failures, but by small problems such as parts that block sensors or get caught in chutes. Although the operator can easily correct such problems when they occur, the frequent halts can dramatically reduce the effectiveness of the equipment.

Reduced Speed Operation

Reduced speed operation refers to the difference between the actual operating speed and the equipment’s designed speed (also referred to as nameplate capacity). There is often a gap between what people believe is the "maximum" speed and the actual designed maximum speed. The goal is to eliminate the gap between the actual speed and the designed speed. Significant losses from reduced speed operation are often neglected or underestimated.

Defect Losses

A defect loss means that the equipment is producing products that do not fully meet the specified quality characteristics. Defect losses include two major types of loss: scrap and rework, and startup losses.

Scrap and Rework

Loss occurs when products do not meet quality specifications, even if they can be reworked to correct the problem. The goal should be zero defects —to make the product right the first time and every time.

Startup Losses

Startup losses are yield losses that occur when production is not immediately stable at equipment startup, so the first products do not meet specifications. This is a latent loss, often accepted as inevitable, and it can be surprisingly large.

OVERALL EQUIPMENT EFFECTIVENESS AND THE TPM VISION

Implementing TPM means striving toward a vision of the ideal manufacturing situation, a vision that encompasses

zero breakdowns

zero abnormalities

zero defects

zero accidents

The path to this ideal situation is a process of continuous improvement that requires the total commitment of everyone in the company, from operators to top management.

In the West, the measure of whether an improvement process is succeeding often rests on the ultimate result of the process: the money it makes or loses. This seems rational, since making money is the ultimate goal of industry. The financial bottom line, however, provides little or no information about what is actually going on within the process; thus it gives little real feedback and focus to the things we actually need to do to improve the process.

If there is a gap between our daily process and the ideal situation, it makes sense to focus on this gap and look for ways to eliminate it.

TPM helps us do this by focusing on the six big losses —the gaps— to improve the effectiveness of the equipment. By applying a gauge that measures the six big losses, we can focus on improving the right things—the losses we want to eliminate.

The Overall Equipment Effectiveness Metric

Most industries have some kind of gauge system on their equipment that measures quantities such as uptime, units produced, and sometimes even the production speed. These are appropriate things to look at if the focus is on what’s coming out of the machine.

TPM takes a slightly different approach. Besides what’s coming out of the machine, we also want to know what could have come out, and where we are losing effectiveness. Overall equipment effectiveness, or OEE, offers a simple but powerful measurement tool to get inside information on what is actually happening.

The OEE calculation is a metric that gives us daily information about how effectively the machine is running and which of the six big losses we need to improve. Overall equipment effectiveness is not the only indicator to assess a production system, but it is certainly very important if our goal is improvement.

THE ELEMENTS OF OVERALL EQUIPMENT EFFECTIVENESS

The three main categories of equipment-related losses —downtime, speed loss, and defect or quality loss— are also the main ingredients for determining the overall equipment effectiveness. Overall equipment effectiveness is calculated by combining three factors that reflect these losses: the availability rate, the performance rate, and the quality rate.

The availability rate is the time the equipment is really running, versus the time it could have been running.

A low availability rate reflects downtime losses:

Equipment failures

Setup and adjustments

The performance rate is the quantity produced during the running time, versus the potential quantity, given the designed speed of the equipment.

A low performance rate reflects speed losses:

Idling and minor stoppages

Reduced speed operation

The quality rate is the amount of good products versus the total amount of products produced.

A low quality rate reflects defect losses:

Scrap and rework

Startup losses

To calculate OEE, we multiply the three factors together:

OEE = Availability Rate x Performance Rate x Quality Rate

The inverted stairstep diagram above shows graphically how the losses in availability, performance, and quality work together to reduce the overall effectiveness of a machine. The top bar, total operating time, shows the total time a machine is available to make a product. This is usually considered to be 480 minutes per 8-hour shift.

Bars A and B show availability. Bar A represents the net operating time, which is the time available for production after subtracting planned downtime (no scheduled production) such as a holiday, no orders, or no personnel.

Bar B shows the actual running time after subtracting downtime losses such as equipment failures and setup and adjustments.

Bars C and D show performance. Bar C represents the Target Output of the machine during the running time, calculated at the designed speed of the machine. Below it, a shorter fourth bar, D, represents the actual output, reflecting speed losses such as minor stoppages and reduced operating speed.

Bars E and F show quality. As you can see, the actual output (E) is reduced by defect losses such as scrap and startup losses, shown as the shaded portion of bar F.

As this diagram shows, the bottom-line good output is only a fraction of what it could be if losses in availability, performance, and quality were reduced. The diagram also suggests that to maximize effectiveness —to grow the good output on the bottom line— you must reduce not only quality losses, but also availability and performance losses. The three factors work together, and the lowest percentage is usually the constraint that most needs addressing.

The Goal and Benefits of OEE Measurement

The goal of measuring OEE is to improve the effectiveness of your equipment. Since equipment effectiveness affects shopfloor employees more than any other group, it is appropriate for them to be involved in tracking OEE and in planning and implementing equipment improvements to reduce lost effectiveness. Let’s look at some of the benefits of OEE measurement for operators and shift leaders or line managers.

We recommend that the operator collect the daily data about the equipment for use in the OEE calculation. Collecting this data will

teach the operator about the equipment

focus the operator’s attention on the losses

grow a feeling of ownership of the equipment

The shift leader or line manager is often the one who will receive the daily operating data from the operator and process it to develop information about the OEE. Working hands on with the data will;

give the leader/manager basic facts and figures on the equipment

help the leader/manager give appropriate feedback to the operators and others involved in equipment improvement

allow the leader to keep management informed about equipment status and improvement results

New OEE Industry Standard Now Available!

Questions about OEE? Ask your OEE Coach!